An experiment in whether algorithms can create things worth keeping.

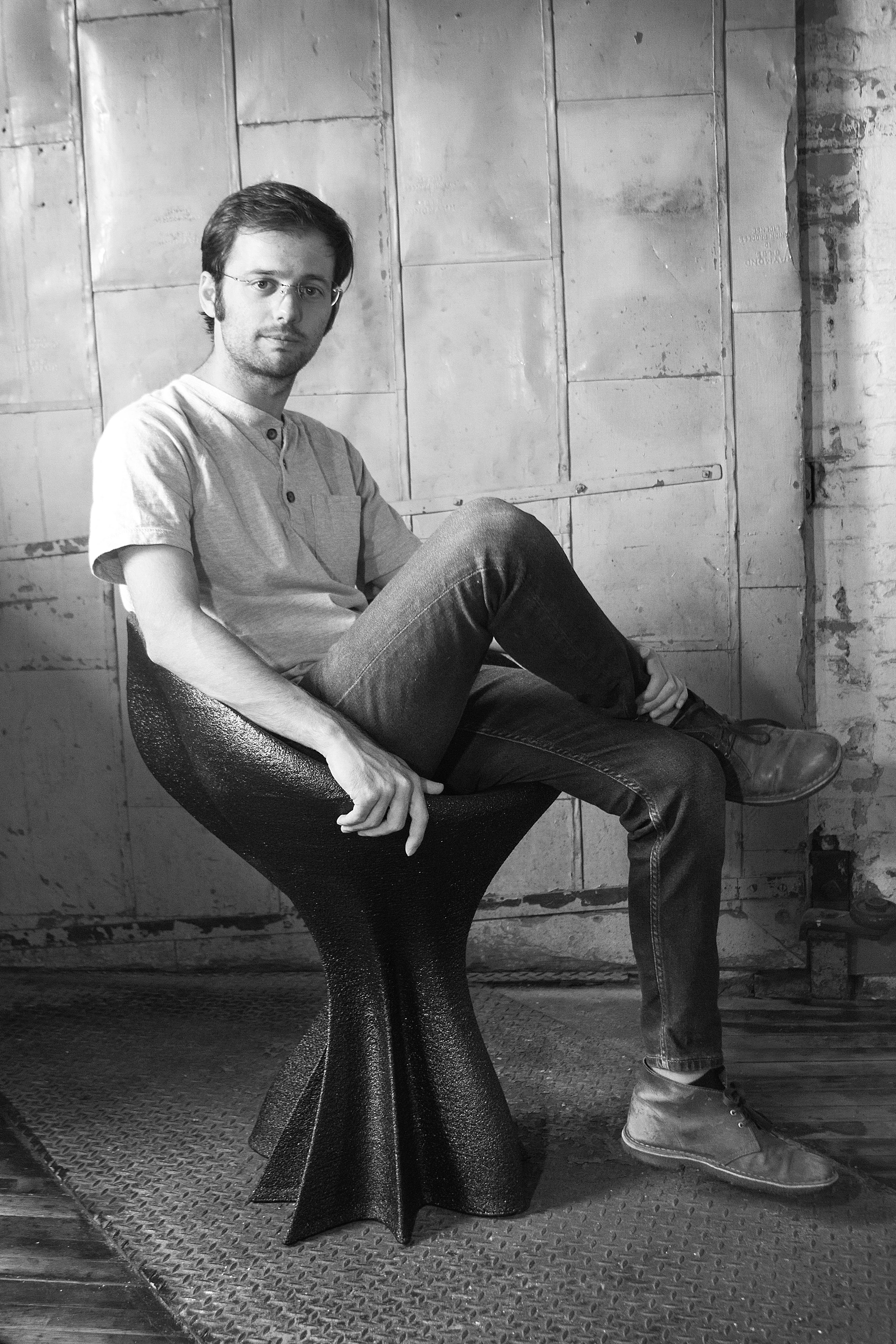

Tree Table

Procedural Generation Recycled Materials Algorithmic Design

An experiment in whether algorithms can create things worth keeping.

What if we didn't have to sculpt each tree? What if we could create a system that grew them for us?

Each one unique. Each one following the same growth logic but arriving at different forms.

How could we make this meaningful? Not just a demonstration of what 3D printing can do, but something people would want to keep, something that honored the natural form we were mimicking?

The limitations became the story. The constraints—using recycled materials, finding discarded glass—made the piece more meaningful, not less.