We built a printer to explore 3D printed furniture.

We built a printer to explore 3D printed furniture.

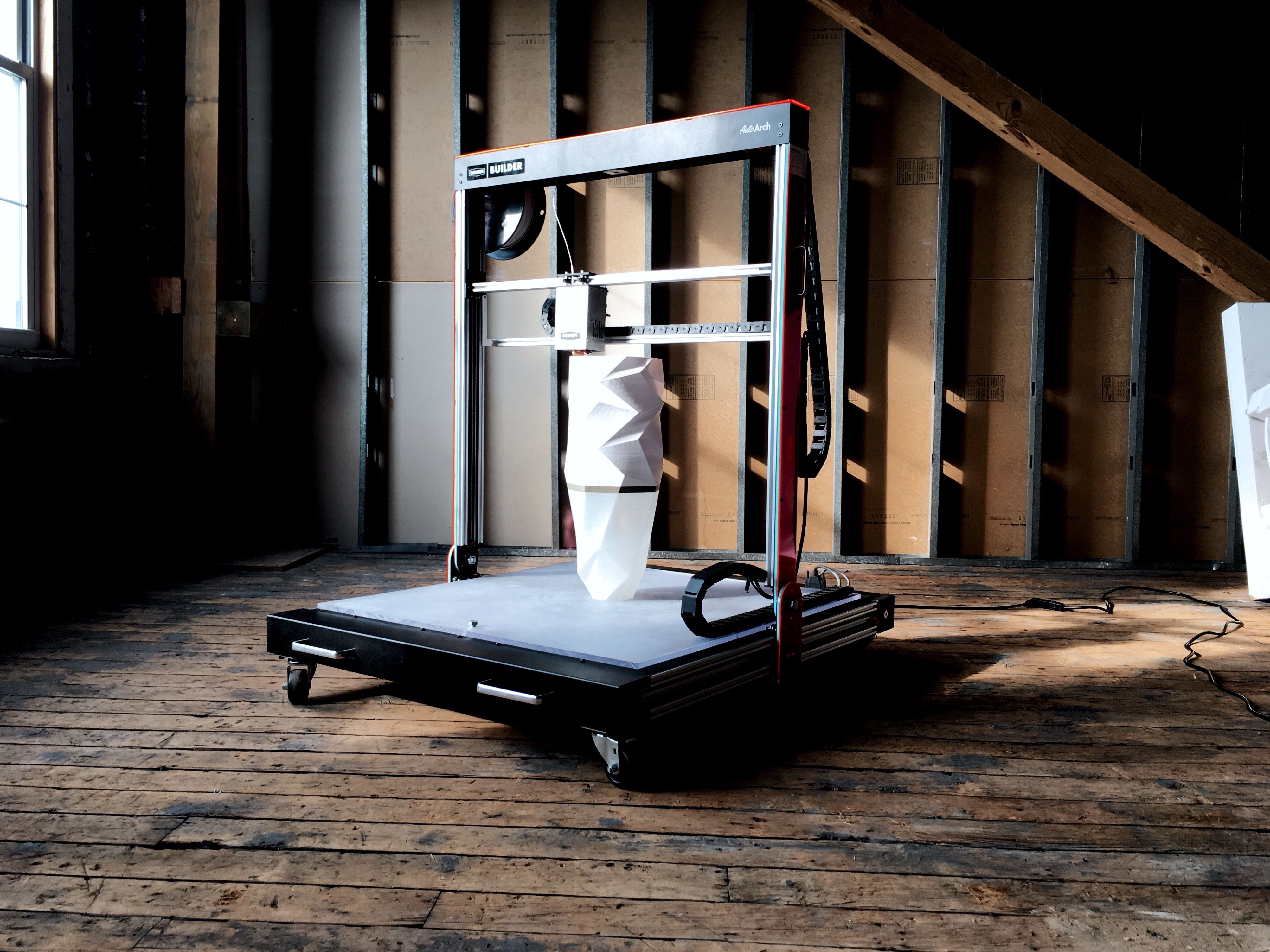

We had built an early version of the Progress printer—our first attempt at a machine that could actually print something at furniture scale.

Traditional furniture is made through forming, extrusion, bending, and assembly. Those processes create certain aesthetics, certain possibilities, certain constraints.

3D printing is different. It's a layering process. It creates one-of-ones, not production runs. And it has its own constraints: it doesn't like unsupported overhangs or cantilevered features—you need scaffolding below, extra material that gets thrown away after.

So we started asking: How would you 3D print furniture that doesn't require any support material?

What forms would emerge from working with the process instead of fighting it?

3D printing doesn't just ask 'how do we make this?' It asks 'what does this process want to become?'

3D printers are great at stacking. Layer on layer on layer. They're also great at curves—the round nozzle moves in arced shapes naturally.

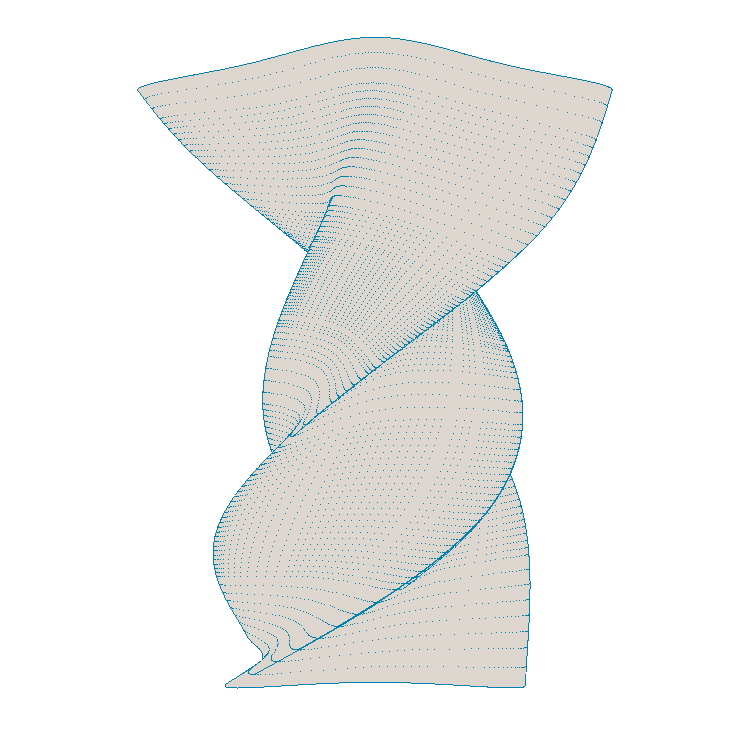

We started thinking: What if we created a spiraling form that could stack on itself? Like whipped cream building up from a piping bag.

We designed a test. A spiraling shape that would become a stool. Printed upside down, forming the seat as a solid layer first, then building the cylindrical walls up layer by layer.

Over about 4 hours, our prototype printer laid down hundreds of layers. We watched it grow, spiraling upward, creating curves and facets that would be nearly impossible to carve from wood or form from injection molding.

When it finished, we were so excited. We popped the stool off the print bed, put it on the floor, and sat down.

The crunch of that first collapsed stool wasn't the end. It was the beginning of the next question.

We loved how quickly it printed. We loved the look of the spiral form. But it couldn't hold weight.

New question: How do we make it stronger?

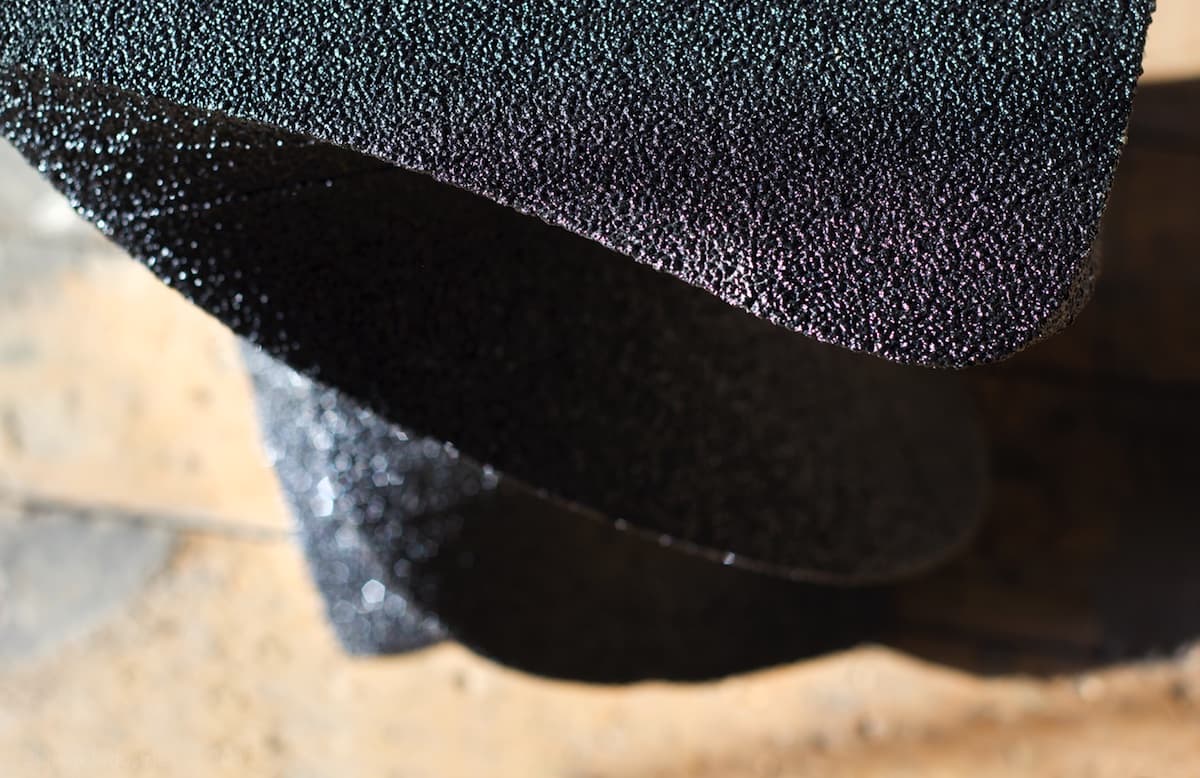

We started talking to material science friends. Together, we developed a structural resin coating that could be applied after printing—a membrane that would reinforce the plastic without changing its form.

After testing, that same collapsed stool design—now coated—could hold someone up to 350 pounds.

And something unexpected happened.

The resin gave the stools a black, slightly textured surface. They looked like igneous rock—like scoria, the dark volcanic rock with its characteristic vesicular texture.

We didn't set out to design furniture that looked like volcanic rock. That was a discovery.

Drag the slider to see how structural resin transforms the stool

Once we had the process working—spiral forms that could support weight, coated in structural resin—we started exploring the geometries, complexities, and curves that 3D printing could create.

Each stool became a unique exploration:

We weren't trying to create a unified aesthetic. We were following the capabilities and constraints of the medium— what 3D printing wants to do naturally .

But when we looked at the collection together, we saw it: a design language that could only come from this process.

Curves that stack. Spirals that support. Textures that strengthen. Forms that celebrate the layer-by-layer nature of additive manufacturing.

This aesthetic—which we came to call Scoria after the volcanic rock it resembles—wasn't planned. It was an answer we discovered.

We weren't trying to create a unified aesthetic. We were following what 3D printing wants to do naturally.

Five original explorations

We started with a question: What does 3D printed furniture look like?

The answer wasn't what we expected. We thought we'd design furniture and then figure out how to print it. Instead, we let the medium tell us what it wanted to be.

We learned:

Traditional furniture asks: "How do we efficiently produce this design?"

3D printed furniture asks: " What forms are uniquely possible with this process? "

The Scoria Stools are our answer so far. But it's an ongoing exploration—the language of additive manufacturing is still being written.

3D printing doesn't just make different furniture. It makes different kinds of furniture.

Each Scoria stool is a one-of-one exploration. We're always open to new collaborations and custom furniture projects that push the boundaries of what's possible with additive manufacturing.