What if 3D printers were open and flexible? The Buildini was designed as an instrument of curiosity.

What if 3D printers were open and flexible? The Buildini was designed as an instrument of curiosity.

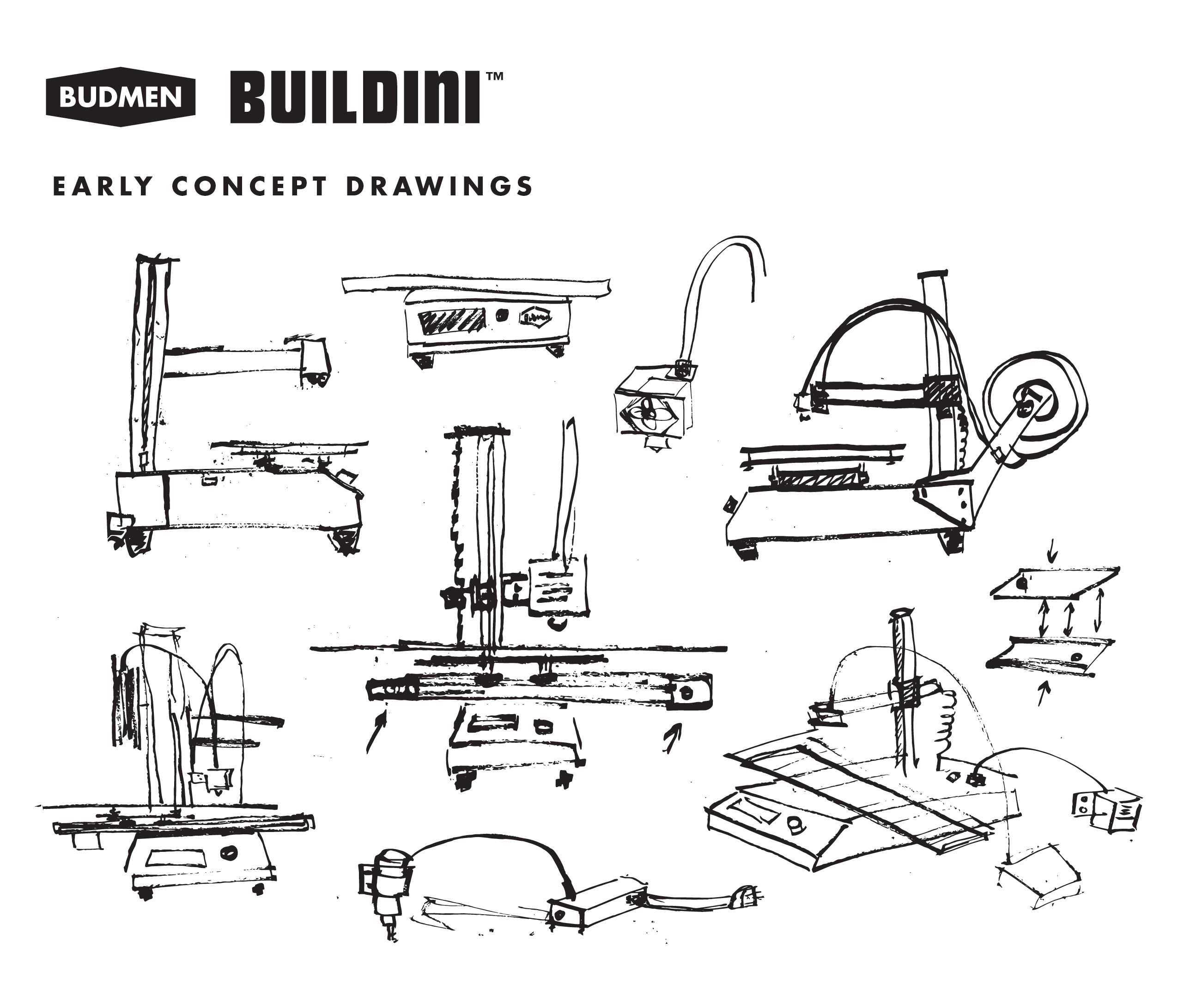

At the time, 3D printers were closed systems. Literally and figuratively.

They were boxes—enclosed, proprietary, single-purpose. If something broke, you couldn't fix it yourself. You had to send it back to the manufacturer and wait for a replacement part. The internals were hidden.

What if 3D printers were open? What if they weren't proprietary? What if they were more open?

What if you could take the extruder off and hand the robot a pen? What if you replaced the extruder with a spindle? What if you could put fabric on the build platform and print directly onto it?

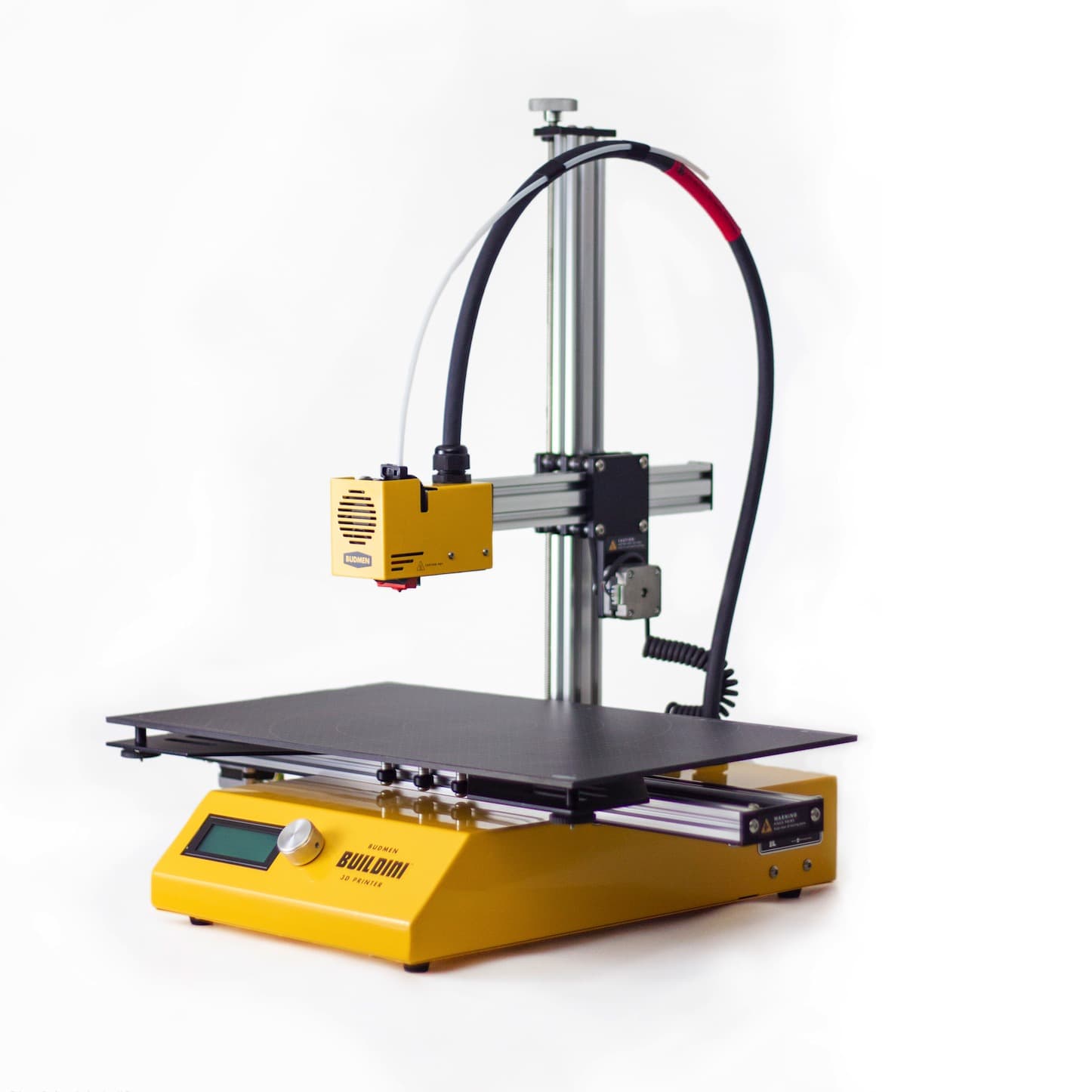

We obsessed over the quality because if people are going to modify and push our tool, it has to be built to withstand that exploration.

All-metal construction. Aerospace-grade aluminum and premium carbon steel. No plastic structural components that would flex or fail.

Million-motion cables. We tested them. Actually tested them—over one million motions. They're rated for thousands of hours of reliable operation because your experiments shouldn't be limited by our shortcuts.

Silent Trinamic stepper drivers. Four of them. Near-silent operation. Big ideas don't have to be loud.

The Spin N Select Knob. Perfectly knurled. Tactile. Satisfying. We went through seven prototypes to get it right. Because starting a print should feel good.

True flexibility means people don't need our permission to experiment.

When every component is visible and accessible, users understand how it works. Understanding breeds modification. Modification breeds discovery. Discovery breeds applications you never designed for.

Cheap components would have limited experimentation. Million-motion cables, aerospace aluminum, silent drivers—quality isn't luxury when people are pushing your tool in unexpected directions. It's infrastructure for discovery.

Watching people push the Buildini taught us what mattered: precision motion, build quality, and radical openness.

Those insights led us to ask a bigger question: What if we could print furniture?

The Progress printer—our large-scale furniture printer—evolved from everything the Buildini taught us. Same philosophy of openness. Same obsession with quality. Just... bigger.

The Buildini was the question that led to bigger questions.

| Title | Buildini 3D Printer |

|---|---|

| Subtitle | An Instrument of Curiosity |

| Years | 2014-2020 (Version 1 to final production) |

| Category | Digital Fabrication Tool |

| Philosophy | Radical openness, user-modifiable, no proprietary parts |

| Build Volume | 18" × 11" × 14" (457mm × 279mm × 356mm) |

| Construction | Aerospace aluminum, premium carbon steel, carbon fiber |

| Manufacturing | Small-batch, high-precision |

| Key Innovation | Universal mounting plate (no proprietary brackets) |

| Notable Users | Fabric Workshop & Museum, independent artists, makers, designers |

| Applications Discovered | 3D printing, robotic drawing, CNC carving, fabric embellishment, laser light art, hybrid fabrication |

| Evolution | Insights directly led to Progress large-scale printer development |

| Status | Lessons learned continue to inform all Budmen tools |