BUDMEN INDUSTRIES PRESENTS

3D Printed Food

When a pastry chef meets a 3D printer, desserts become answers to curious questions.

WHAT IF YOU COULD 3D PRINT FOOD?

Stephanie had spent years working as a pastry chef in Chicago—in bakeries, for Michelin-star chefs, and in all sorts of culinary environments—perfecting and honing her craft. When Stephanie and Isaac started working together, there was a natural intersection their curiosity needed to explore.

Food and 3D Printing

Finding the Right Medium

The Syringe Experiment

We thought the best way to start would be to fail quickly.

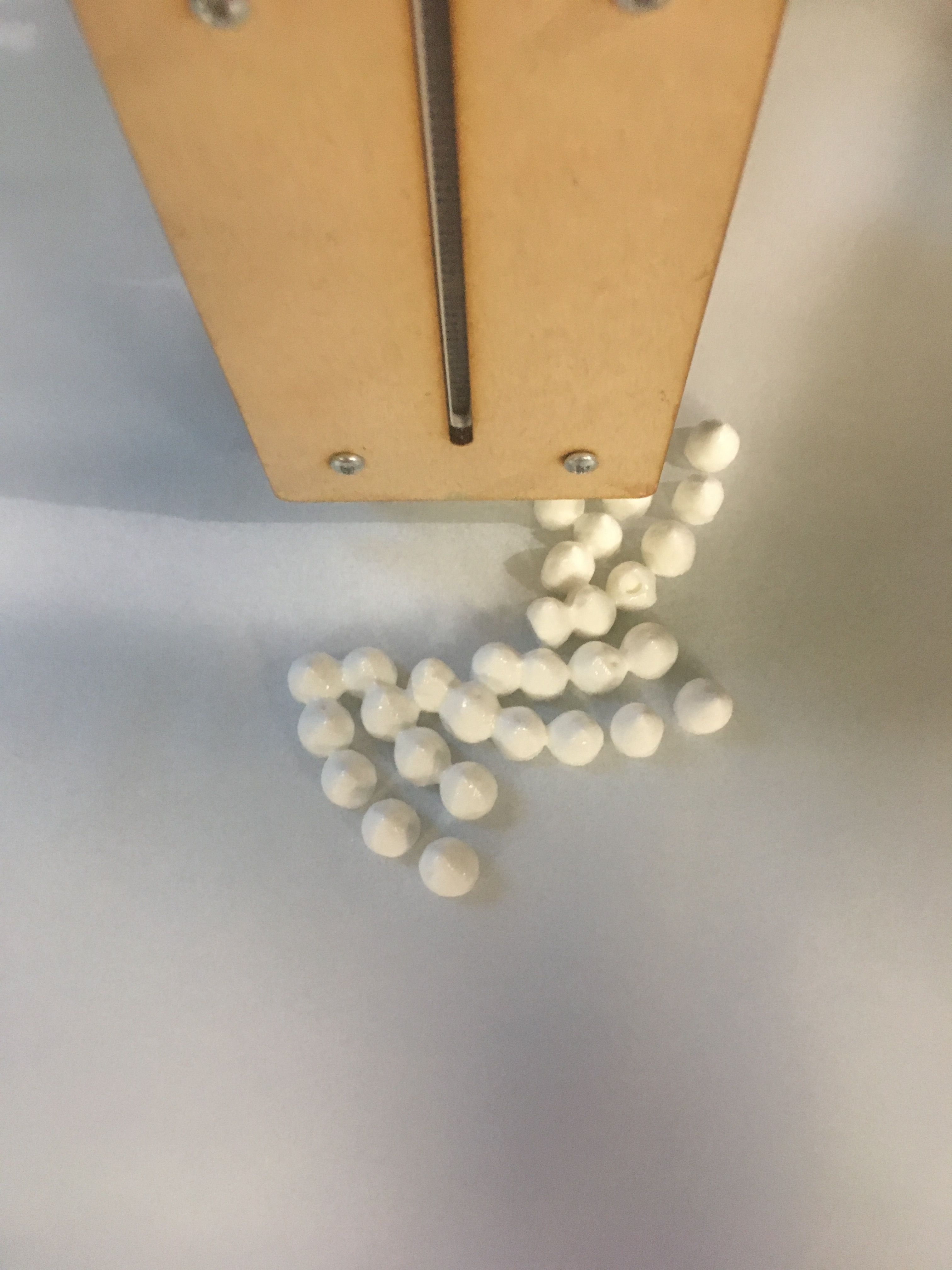

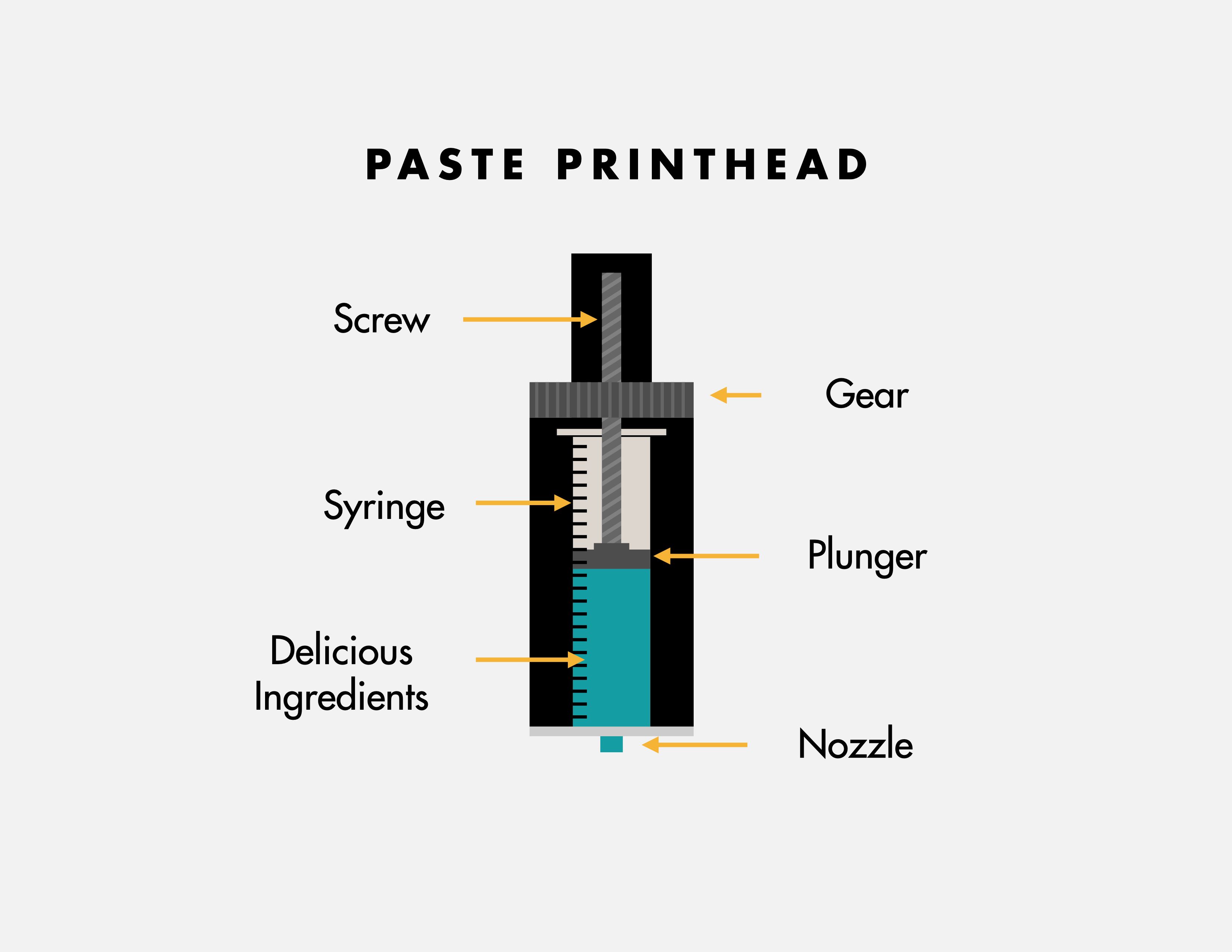

We grabbed some syringes—standard syringes, the type you might use to give your pet medicine. If we could fill the syringe with delicious ingredients and create a device that could control the plunge rate, could we control the rate at which ingredients were extruded?

We might be able to 3D print food.

Over a couple of days, we prototyped a food 3D printer: A cutting board as the build platform. A system to position the print head above the plate wherever we needed it. Syringe plunger controls.

It was crude. It was makeshift. It was ready to test.

FOOD

Inspiration: Robert Indiana's iconic LOVE sculpture

It looked like shit.

The first attempt: not appetizing. The F had lost its fidelity. The O had gotten smeared.

Maybe the room was too warm? Maybe the ingredient wasn't the right one for printing and for holding shape? What other ingredients could we try?

Back to the Drawing Board

Of course. That's why pie tins exist.

Vertical printing: butter melted out, structure collapsed

Horizontal printing: structure held, golden and beautiful

Lemon meringue pie assembled with 3D printed horizontal fractal pie crust

French Macarons Reimagined

French macarons—those really delicate, beautiful cookie sandwiches. We'd only ever seen them round. What if they could be a different shape? Shareable? Totally different?

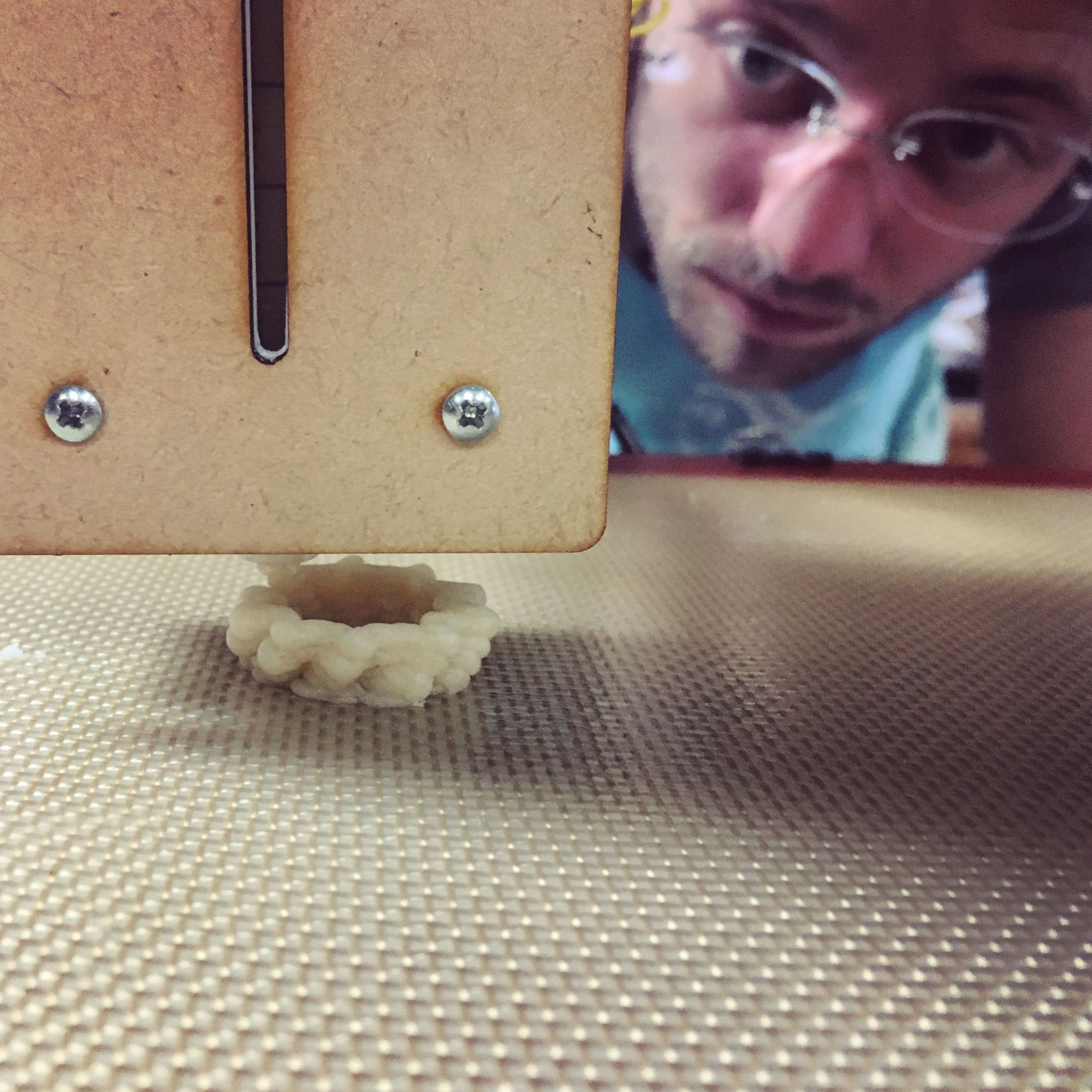

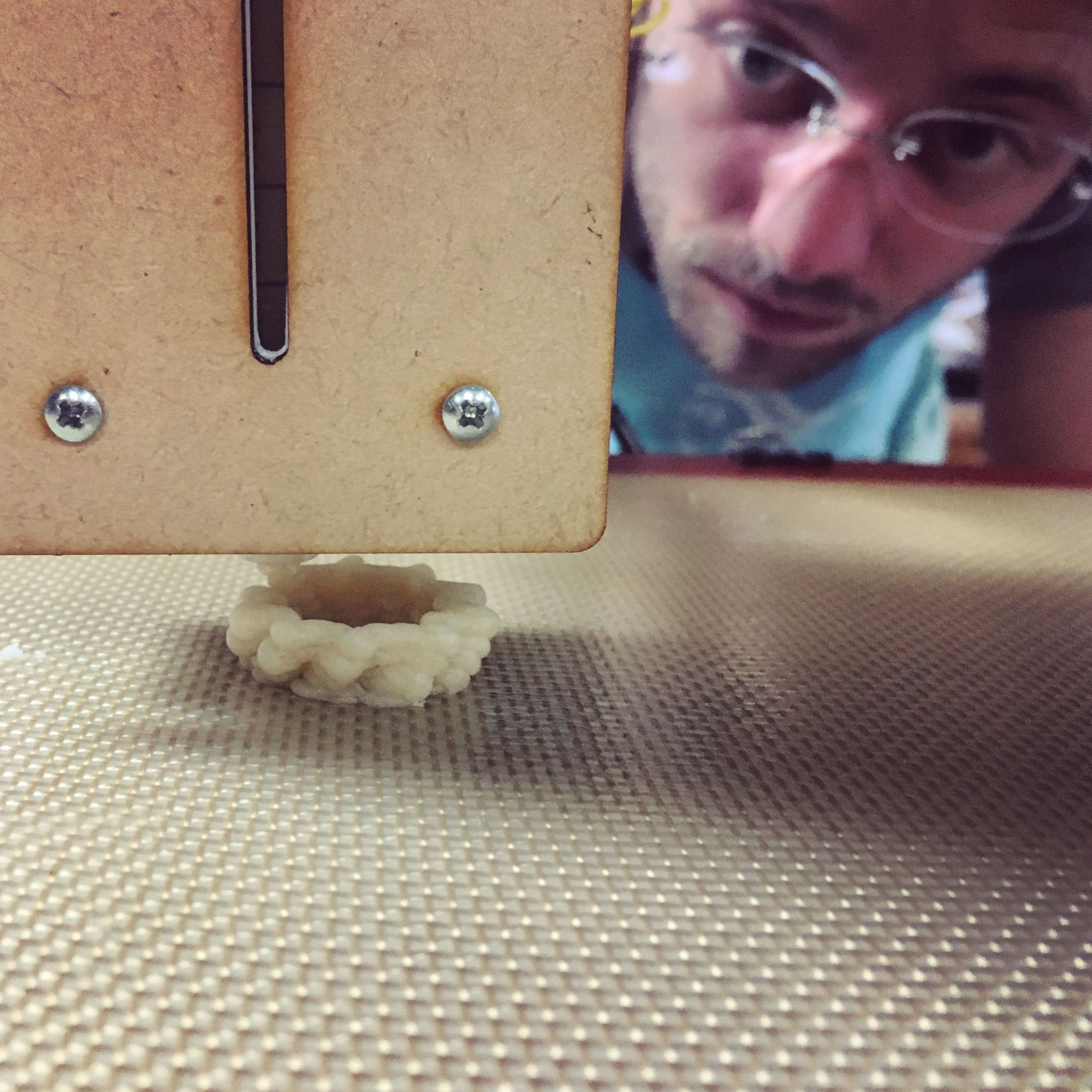

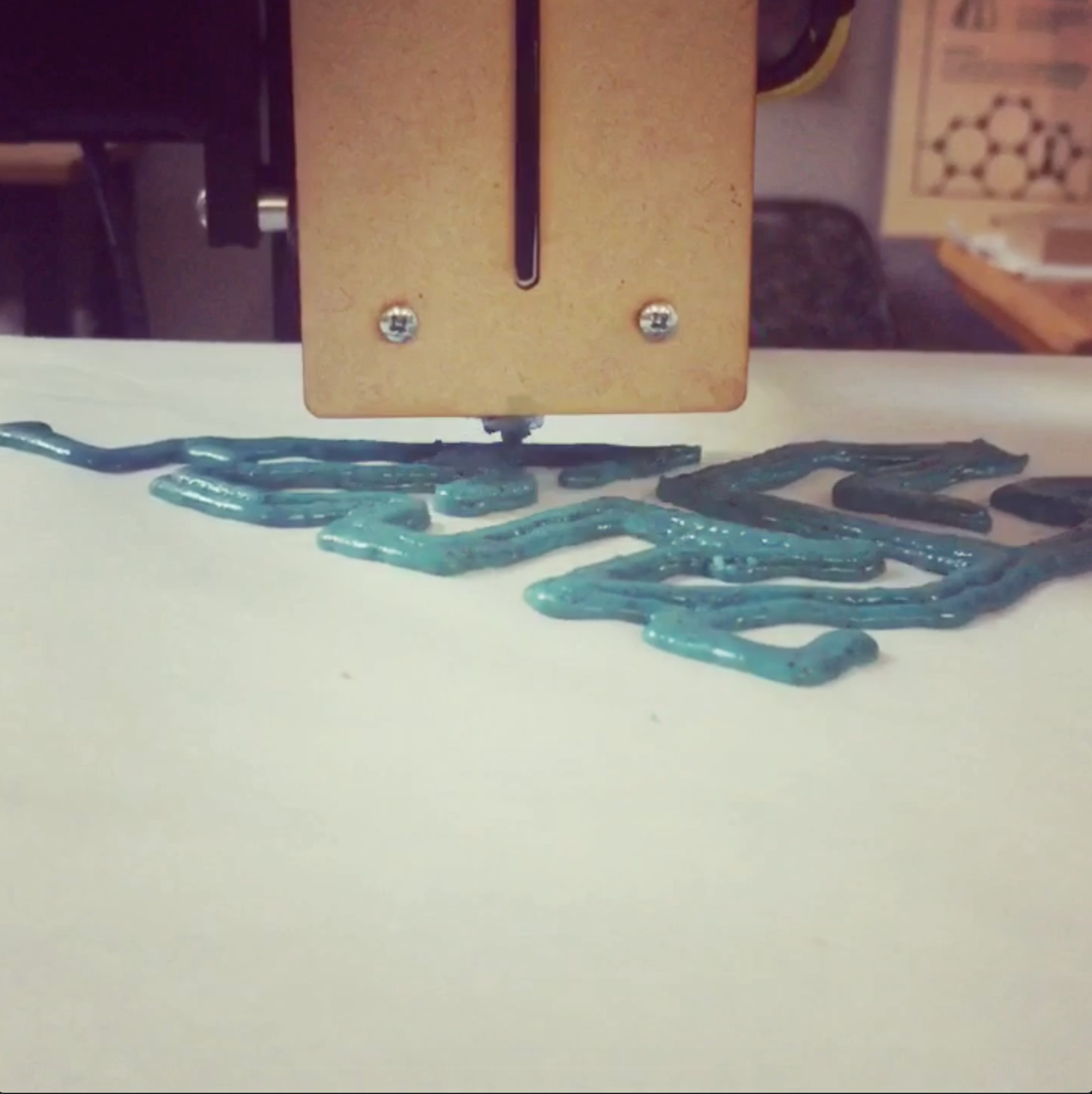

We designed a geometric fractal shape, loaded up the printer with blueberry macaron batter, and printed.

They turned out awesome.

We even took them to an event. Funny enough, when folks saw the 3D printed desserts in bright blue, red, and white, they thought they were made from plastic. Decorative. Not realizing these amazing desserts could actually be eaten.

No one had ever had a French macaron that looked like this.

Moving Like a Pastry Chef

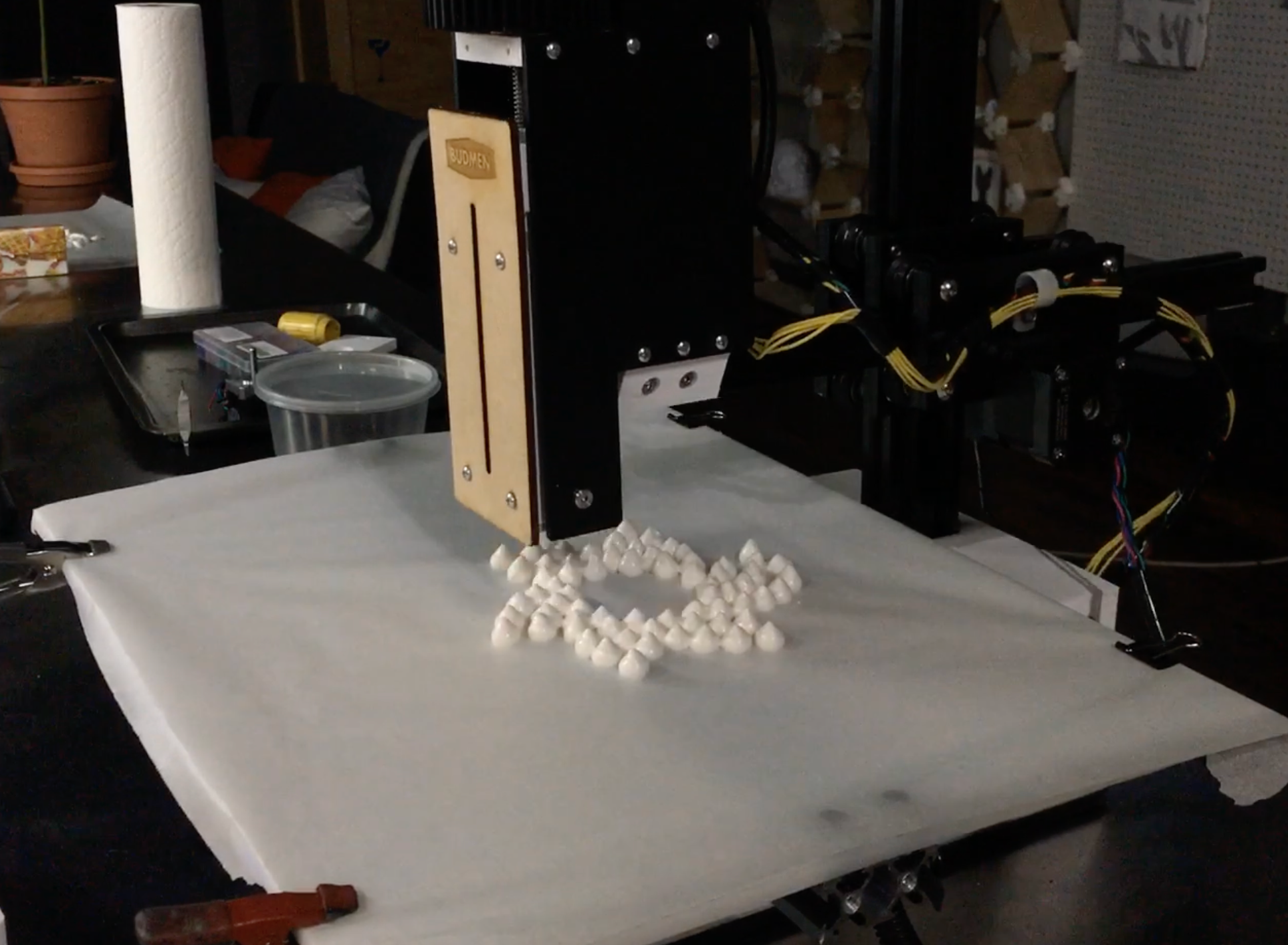

Nature's blueprint: Fibonacci spiral in the face of sunflowers

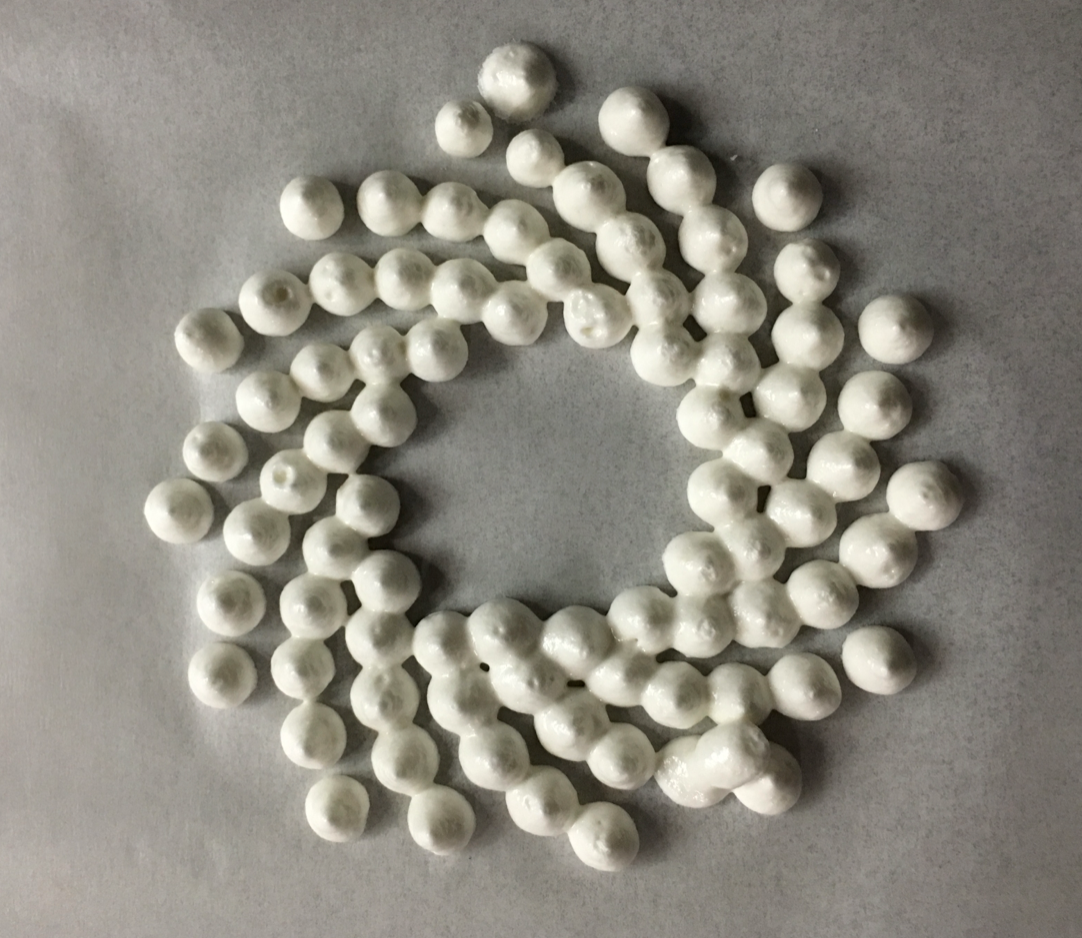

Robot precision: dolloped Kiss shapes forming the Fibonacci sequence

Culinary elevation: Chef Steph's avant-garde strawberry shortcake

Desserts as answers, not designs.

What Food Taught Us

The most beautiful results come from letting the process teach you, not forcing your vision onto it.

The Results

What We Learned About Making

| Title | 3D Printed Food Experiments |

|---|---|

| Year | 2015 |

| Location | Philadelphia, PA |

| Category | Culinary Innovation, Digital Fabrication |

| Collaboration | Chef Stephanie Budmen + Isaac Budmen |

| Technology | Modified FDM 3D printer with syringe-based paste extrusion |

| Ingredients Tested | Chocolate frosting, pie dough, macaron batter, various pastes |

| Notable Creations | FOOD sculpture, fractal pie crust, geometric macarons, Fibonacci strawberry shortcake |

| Key Innovation | Dollop motion behavior—teaching printer to move like a pastry chef |

| Philosophy | Desserts as answers to curiosity, not predetermined designs |

| Status | Ongoing exploration of food as fabrication medium |

Now that we can print food, what else can we print that behaves unlike plastic?